Table salt is sodium chloride, limestone is

calcium carbonate, and water is hydrogen oxide.

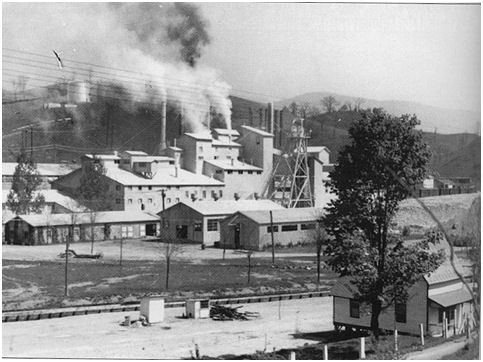

The first chemical process Mathieson used

in its chemical factory at Saltville simply

switched the partners around in these two

compounds by a two part chemical process.

United States Gypsum of Plasterco

In a chemical process called ‘the Solvay Process’ sodium

chloride and calcium carbonate are changed into sodium

carbonate and calcium chloride.

Limestone was quarried in

Walker’s Mountain to the south of town, and was brought

in by ore buckets carried on a high cable system.

Then carbon dioxide from

the air and ammonia can be added and sodium bicarbonate

(baking soda) was made.

In the second type of manufacturing process limestone

was mixed with salt water, which was pumped from wells.

The resulting chemical reaction is called the

‘chloralkali process’ (Castner-Kellner Process).

An electric current is run through salt water,

and the result is hydrogen gas, chlorine gas, and sodium

hydroxide (lye).

Mercury is required to make this process work.

It is not consumed, but leaks out of the

machinery in the process of manufacture.

The machine unit used in this process is called a

‘mercury cell’.

In the early years the commercially useful end

products of these processes were sodium carbonate,

also known as ‘soda ash’, which is used in glass

manufacture; sodium bicarbonate, which is baking

soda and which was sold under

... Continue

to PAGE 54